|

|

Post by Knight Woodworks on Jun 24, 2015 18:45:57 GMT -5

GhostFist,

Fair enough, if it gets to be a burden let us know. I for one would be happy to contribute.

Red,

Sorry for the off topic discussion. Your TF tools are way cool.

John

|

|

|

|

Post by Red on Jun 24, 2015 20:09:43 GMT -5

No worries, John. You can chat about whatever you like on any of my threads, but I'd still appreciate any thoughts you might have about the thread topic ... while you're here.

|

|

|

|

Post by holmz on Jul 10, 2015 19:44:46 GMT -5

Hi Red.

I went by the wood yard today.

Nothing bigger than 4x4, but they LVLs (glulams).

Do you have a cutting list for the ponies?

Will glulams work?

|

|

|

|

Post by Red on Jul 11, 2015 3:38:09 GMT -5

I could mill you out some small timbers, but I've got a funny feeling that shipping them to Oz

would be cost-prohibitive.

As for glulams ... I've never touched one with a chisel. They're strong enough, no doubt about

that, but I'm not sure about how well traditional TF tools would cut "engineered" wood products.

Having written that, however, you could always give 'er a go and resharpen when and if necessary.

Please send me a separate message reminding me about the Trestle Pony cut list.

|

|

|

|

Post by Red on Jul 12, 2015 2:39:25 GMT -5

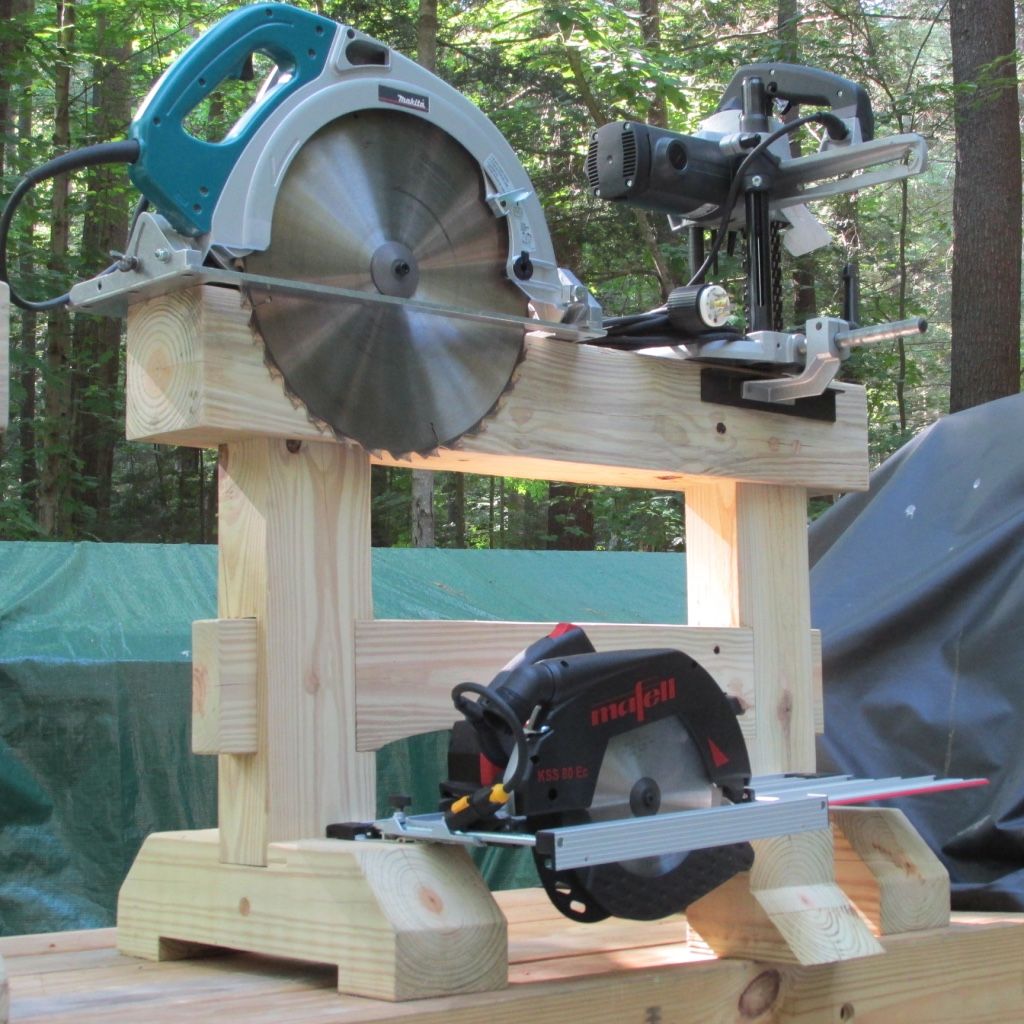

Our unofficial photographer has a flare for the dramatic, obviously, but this is a pretty decent shot of our beam saw, nevertheless. If nothing else, it clearly shows the depth of cut obtainable by its 16-5/16 blade. It's not really visible in the photo, but the "less than ideal" stamped steel OEM base has been replaced by a larger custom-made aluminum unit.

|

|

mattuk

Junior Member

Posts: 79

|

Post by mattuk on Oct 30, 2015 17:37:19 GMT -5

Seeing the Makita saw dwarf the KSS80 certainly gives it a sense of scale.

Red, thanks for the shots.

Have you ever used the Barr slick ?

I have 52 tenons awaiting me in Oak and wonder what best to finish the tenons with?

I have seen reference to barrs, Robert sorby slick, beautiful Japanese creations and even John Neemans offerings from Estonia.

I would rather purchase well, once.

I have another project early next year involving more tenons being created in Azobe.

I am fortunate that I weigh in at 230 and should be able to persuade the steel through the timber.

Thanks in advance for any advice.

|

|

|

|

Post by holmz on Oct 30, 2015 19:42:42 GMT -5

Sounds like you are considering a slick over a chisel and mallet?

All the options you mentioned are sounding like the creme de la creme of the options.

I have not yet used the bisague for fine removal. You need to consider how the material is held. 230# (~100kg) will move the tool, which exerts force on the material, which exerts a strain on the holder of the material.

IMhO opinion, you may be better off considering ponies and horses or tables that facilitate what ever tool is used prior to the tool... Maybe mallet is easier but slicks/bisaques make it more of a concern??

|

|

|

|

Post by Red on Oct 31, 2015 1:20:44 GMT -5

Seeing the Makita saw dwarf the KSS80 certainly gives it a sense of scale. Red, thanks for the shots. Have you ever used the Barr slick ? I have 52 tenons awaiting me in Oak and wonder what best to finish the tenons with? I have seen reference to barrs, Robert sorby slick, beautiful Japanese creations and even John Neemans offerings from Estonia. I would rather purchase well, once. I have another project early next year involving more tenons being created in Azobe. I am fortunate that I weigh in at 230 and should be able to persuade the steel through the timber. Thanks in advance for any advice.

Although I don't presently own one, I have used a large Barr slick for scarfs (mostly). I've also used one for gunstock posts, as well, and they're quite effective for getting down to the line: on long cuts. Unless the tenons you mentioned are quite long, I'd steer you toward a shorter high-quality chisel. If you read through the timber framing threads I've started and/or participated in, you'll soon learn that I favor the tools forged by Barr Quarton. They're not the hardest TF tools available, however, so they require their share of care. When cared for properly: they are very very effective.

It's been mentioned in more than one old thread, but I've worked with a master joint cutter who works almost exclusively with northeastern Red Oak. Due to how they hold an edge, he prefers Japanese chisels, but they also require proper care. Sharpening them, for instance, requires some real skill -- and unless you're fairly adept at sharpening -- this puts them in the realm of "advanced" timber framing chisels.

Perhaps you could share a few more details about the tenon work you're faced with and, in return, I'll give the "ideal" chisel a bit more thought?

Like yourself, I block more than my share of sunlight, so I'm usually the one swinging the commander at frame-raising time.  |

|

|

|

Post by holmz on Oct 31, 2015 1:56:00 GMT -5

I busted out the Tormek today.

They said it was 230v, but the 110v plug made me take pause.

I sharpened 2 knives. A cheap SS one, and a Japanese one.

Both came out OK, but I took to both with a wet stone afterwards.

The Japanese one came good, and the SS one not so sharp.

Going to the garage to hunt down some chisels...

@red do you use hand stones or rough the edge in with a machine?

<later...>

Well the square guide seems to cut crooked. Both planes now have a slight angle on their blades.

|

|

|

|

Post by Red on Oct 31, 2015 11:51:33 GMT -5

I busted out the Tormek today. They said it was 230v, but the 110v plug made me take pause. I sharpened 2 knives. A cheap SS one, and a Japanese one. Both came out OK, but I took to both with a wet stone afterwards. The Japanese one came good, and the SS one not so sharp. Going to the garage to hunt down some chisels... @red do you use hand stones or rough the edge in with a machine? <later...> Well the square guide seems to cut crooked. Both planes now have a slight angle on their blades.

you'll get the results you're after. My first thought is that your stone and your guide jig aren't in

alignment. The stone must be ground to match your stone before you put your precious blade

steel on it...

As for your question, other than the occasional on-the-job block stropping, we use the Tormek T-7

for just about all aspects of sharpening now. Keep working with your Tormek unit -- and you should,

in the end, get great results. |

|

mattuk

Junior Member

Posts: 79

|

Post by mattuk on Oct 31, 2015 12:35:10 GMT -5

Thanks holmz and Red, The truss is formed in 8" x 5" I have a couple of smaller veritas bench chisels ( up to 1" ) but fancied something larger for the mass of tenons heading my way. I look forward to any advice. If a chisel and mallet is a better option then I am fine with that. Red, would the Barr tools listed on the site below be the same as the Barr Quarton that you use ? If so, that would make things a little simpler because they are local. www.classichandtools.com/acatalog/Barr-Specialty-Chisels.htmlI look forward to your replies. Best regards Matt |

|

mattuk

Junior Member

Posts: 79

|

Post by mattuk on Oct 31, 2015 12:39:48 GMT -5

I grabbed a couple of screen shots from the rough cad drawing. Hopefully they will visible below. |

|

mattuk

Junior Member

Posts: 79

|

Post by mattuk on Oct 31, 2015 12:41:51 GMT -5

It is being constructed within a building as ornamental. The roof shall be formed in plasterboard only, so no tiles or snow loading to allow for  |

|

|

|

Post by holmz on Oct 31, 2015 19:54:30 GMT -5

I busted out the Tormek today. Red do you use the Std stone or Japanese (4000 gr) one? I probably need to make the stone for inside and outside or leave it on the machine. |

|

|

|

Post by Red on Nov 1, 2015 2:13:43 GMT -5

The truss is formed in 8" x 5" I have a couple of smaller veritas bench chisels ( up to 1" ) but fancied something larger for the mass of tenons heading my way. I look forward to any advice. If a chisel and mallet is a better option then I am fine with that. Red, would the Barr tools listed on the site below be the same as the Barr Quarton that you use ? If so, that would make things a little simpler because they are local. It is being constructed within a building as ornamental. The roof shall be formed in plasterboard only, so no tiles or snow loading to allow for

In case I've confused you somehow, Barr Quarton (BQ) is the name of the Japanese-trained blacksmith who started and runs Barr Specialty Tools in Idaho. Barr has a very simple way of identifying his tools..."FC" means Framing Chisel, "BC" means Bench Chisel, "CC" means Corner Chisel and so on. The fact that these simple acronyms can be found via the hyperlink you posted leads me to believe that they're authentic hand-forged Barr Quarton socket chisels...and unless things have changed dramatically since I was last in the UK, they seem rather expensive (via your internet-based supplier).

Given what I've read, thus far, I'm leaning toward either a 1-1/2 inch or a 2-inch BQ framing chisel and, obviously, a well-balanced [very] hardwood mallet. Blunt chisels are very dangerous, not to mention insanely-frustrating, so you'll need some sort of an effective sharpening system to keep your high-quality chisels -- whatever the brand -- sharpened and properly honed. It's a long story, but we ended up with a Tormek T-7 system and, when used properly, it renders excellent results.

Once I know exactly what you're going to be working on, perhaps I can help you out with actual tool acquisition...and, by the way, it might be a good idea for you to read through some of the other TF threads here on the forum.  |

|