iban

Full Member

Posts: 111

|

Post by iban on Dec 16, 2020 15:48:31 GMT -5

Hi.

I can get a second hand dd40p quite cheap. Does it worth it? I haven´t heard too much good things about it.

Also I have to mention that the 2 bits are not aligned by 1mm. One is higher than the other.

Is this something you can live with??

|

|

|

|

Post by Knight Woodworks on Dec 16, 2020 16:28:02 GMT -5

I like mine. Is the misalignment a function of a bad bit or a defective machine? If it’s the tool itself don’t buy it. It’s not something you could live with.

John

|

|

iban

Full Member

Posts: 111

|

Post by iban on Dec 16, 2020 17:35:06 GMT -5

I think it´s the tool itself. I don´t know if it has an easy fixing or not but the price is really good...

|

|

|

|

Post by Knight Woodworks on Dec 16, 2020 18:41:30 GMT -5

There is no adjustment in the setting, unlike the Festool Domino or slop in the mortise like a biscuit joiner. I’m somewhat doubtful that there is an easy fix in this instance.

Good luck.

John

|

|

|

|

Post by fuzzylogic on Dec 16, 2020 22:01:18 GMT -5

iban: the Duo-Dowel System DD40P is a precision machine, that serves its designed purpose very well - if the price is right for you, maybe worth sending in for a service?

Richard (UK)

|

|

iban

Full Member

Posts: 111

|

Post by iban on Dec 17, 2020 0:10:06 GMT -5

I don't know how much would take it to repair. Price is 150€

Anyone had any experience in repairs with mafell tools?

|

|

|

|

Post by alvychippy on Dec 17, 2020 12:48:30 GMT -5

I don't know how much would take it to repair. Price is 150€ Anyone had any experience in repairs with mafell tools? Seriously, you and your bargains... For that "price" it's no brainer, take it and run As it comes to repairs (don't own one), it'll be dropped and only way to fix it is to replace whole mounting frame... that might cost double of what you'd pay, but if any less is only a win. Talking about it, as long as you have a proof of legitimate purchase, it's very likely to be within 3 year warranty, you might get it fixed free |

|

|

|

Post by aas on Dec 17, 2020 15:06:30 GMT -5

It depends what you mean by higher... it is almost impossible that the lateral height is not level - if you're talking about length, it suggests one of the cutters is either badly seated, or has been over sharpened. For 150, take the punt.

|

|

iban

Full Member

Posts: 111

|

Post by iban on Dec 18, 2020 9:43:26 GMT -5

I don't know how much would take it to repair. Price is 150€ Anyone had any experience in repairs with mafell tools? Seriously, you and your bargains... For that "price" it's no brainer, take it and run As it comes to repairs (don't own one), it'll be dropped and only way to fix it is to replace whole mounting frame... that might cost double of what you'd pay, but if any less is only a win. Talking about it, as long as you have a proof of legitimate purchase, it's very likely to be within 3 year warranty, you might get it fixed free What can I say... I want to keep my money but people insist in taking it... 😪 Is second hand so no warranty. I would need to try fixing by myself making you lots and lots of questions 😁 It is not deeper as far as I know. One is lower from the edge reference. Not aligned if you know what I'm trying to say |

|

iban

Full Member

Posts: 111

|

Post by iban on Dec 23, 2020 17:38:56 GMT -5

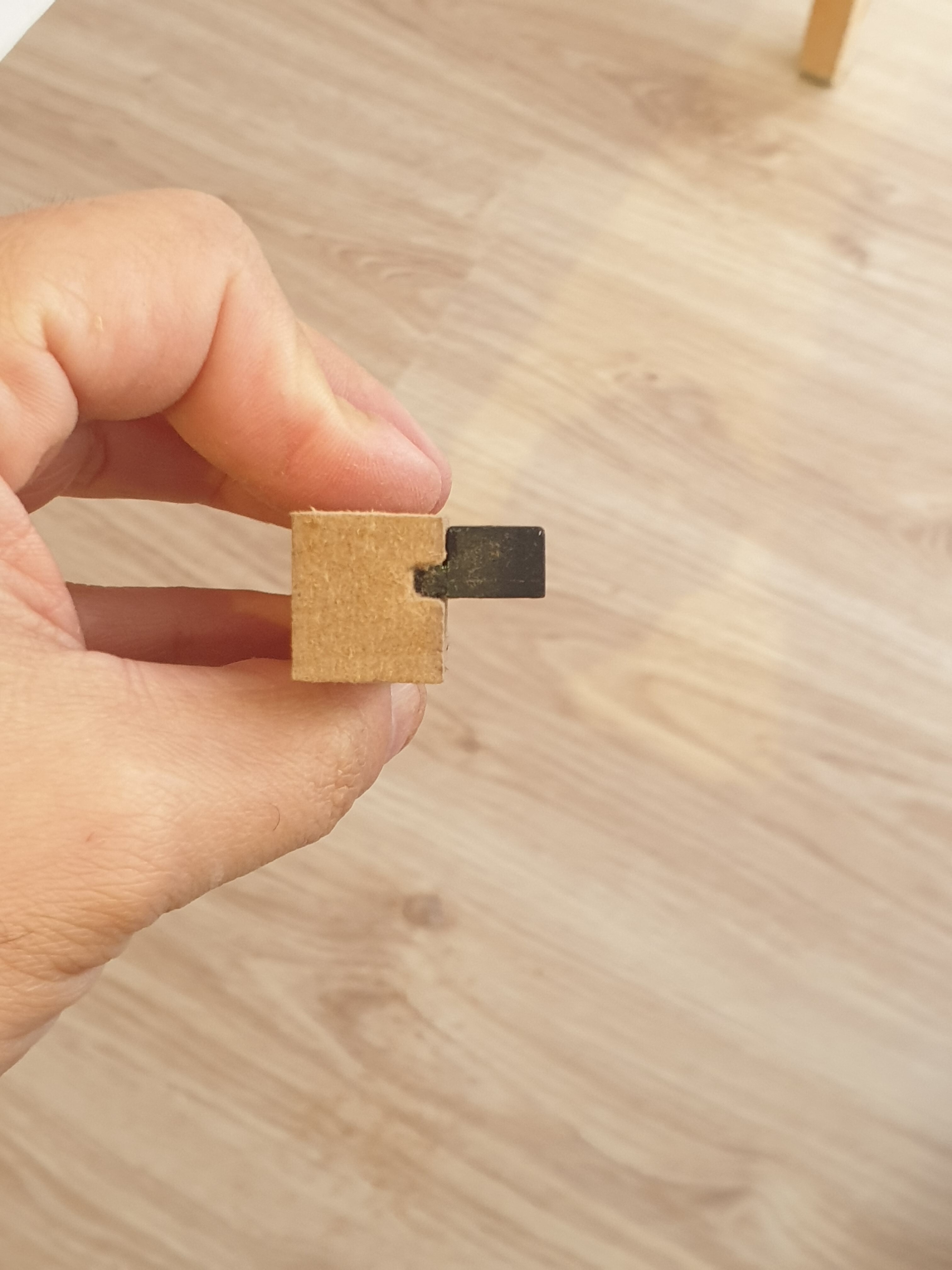

Received and yes, holes are not aligned.

I'm trying to modify the angle of the frame in relation with the motor. Adding some washers under the plastic piece with 3 screws which goes in a groove and guides the plunge I increased the misalignement so I understand I need to file the plastic piece to compensate.

|

|

|

|

Post by aas on Dec 24, 2020 3:01:49 GMT -5

Do you have photos of the misalignment - still trying to work out 'how'

|

|

iban

Full Member

Posts: 111

|

Post by iban on Dec 24, 2020 9:53:38 GMT -5

|

|

|

|

Post by aas on Dec 24, 2020 12:40:44 GMT -5

Try : vgy.me/...works here OK. I understand the result you are having, I don't understand how the tool is twisted or misadjusted to provide this result. The photos you have linked to don't seem to show the cause of the problem, just the result. |

|

|

|

Post by alvychippy on Dec 24, 2020 14:46:58 GMT -5

Received and yes, holes are not aligned. I'm trying to modify the angle of the frame in relation with the motor. Adding some washers under the plastic piece with 3 screws which goes in a groove and guides the plunge I increased the misalignement so I understand I need to file the plastic piece to compensate. As suspected... If anything, considering the twist at a "entry" doesn't it go squwed deeper in? I mean if you twist the base to get drill to enter equally, will it not make not round entry if to hold the machine firmly?  |

|

iban

Full Member

Posts: 111

|

Post by iban on Dec 26, 2020 18:46:24 GMT -5

Received and yes, holes are not aligned. I'm trying to modify the angle of the frame in relation with the motor. Adding some washers under the plastic piece with 3 screws which goes in a groove and guides the plunge I increased the misalignement so I understand I need to file the plastic piece to compensate. As suspected... If anything, considering the twist at a "entry" doesn't it go squwed deeper in? I mean if you twist the base to get drill to enter equally, will it not make not round entry if to hold the machine firmly?  I think I don´t get what you mean... It´s difficult for me to explain but I´ll try. Not sure what is the cause of the not paralel holes as it does not show any hits or scratches. Thanks to a friend who has the machine and helped me to locate the piece that guides the machine when plunging. Adding washers or filing the piece twists the motor with the metal as an axis.    In my case I needed to file the piece without touching the lip. I made a jig to helping me filing evenly and square   After some time filing and testing I got what I find very usable.   Now I´m going to buy the missing transparent window and the red plastic pins. Also a Makita systainer which is 1/3 the price of a original one and I think it is still stackable with Mafell´s, Festool´s and others. |

|