|

|

Post by henrun on Jan 1, 2017 7:53:53 GMT -5

Hi all! I did browse and search the Forum but could not find a conclusive answer to the my question while sifting to the threads: Do the Bosch 165mm blades fit the MT55cc, yes or no? I am selling off my Bosch GKT55ce due to limited use and I have two new Bosch Optiline blades that I am keen to keep if they work on my MT55cc. The difference in cutting depth aside (which does not bother me) I would like to hear from anyone who has actually tried it or is using 165mm blades on the MT55cc. Yes, I know I could go ahead and bring the Bosch blades from the workshop and fit them to the MT55cc but if anyone tells me there is no point in doing so then I don't have to ruin the blades and score the inside of the housing unnecessarily.  |

|

|

|

Post by oncomeme on Jan 2, 2017 23:28:39 GMT -5

You don't have to turn the saw on to see if it fits. The arbors seem the same but my guess is the extra 3mm will mean the blade never fully retracts.

|

|

|

|

Post by reflector on Jan 4, 2017 9:52:11 GMT -5

I swore I saw someone wrote that they tried sticking in a 165mm Bosch blade into their MT55cc and it worked. I asked them to confirm but they never responded. This is something I'll have to look for a while to find since I can't find it immediately.

I think you'll be better off sticking the sawblade into your MT55cc to visually check if they fit, you're more likely to figure that one out than finding someone else who experiments like that. I'm in the US so ordering those would be somewhat of a challenge for me (Not to mention it would really, really suck if they didn't fit) and I've already found the blades I'll be sticking with (See the Sawblade data thread with the Tenryus)

You might want to leave the flange not fully tightened and try to "wiggle" the blade back and forth towards the housing and away from it to see if there's any interference from just runout if the blade isn't perfectly mounted.

|

|

|

|

Post by holmz on Jan 4, 2017 12:43:38 GMT -5

I can see if I have one, but I am in the US at the moment.

I have a lot of MT55 blades.

|

|

|

|

Post by henrun on Jan 4, 2017 15:42:51 GMT -5

Ok, thank you guys. I will try it as suggested and wiggle it around and if ok, I will test it myself tomorrow and report back. I am not too worried if the blade would stick out a mm or two from the housing, but scoring the housing is a no go. I am really happy with the Bosch 48T blades (optiline for wood) and it turns out I have two spares so I would love to be able to use them on the MT55cc. Will get back tomorrow night with my findings.  / Henrik |

|

|

|

Post by holmz on Jan 4, 2017 18:40:40 GMT -5

Or just measure the clearance with the 48T blade... Should be > 3-mm and then you should clear the housing.

|

|

|

|

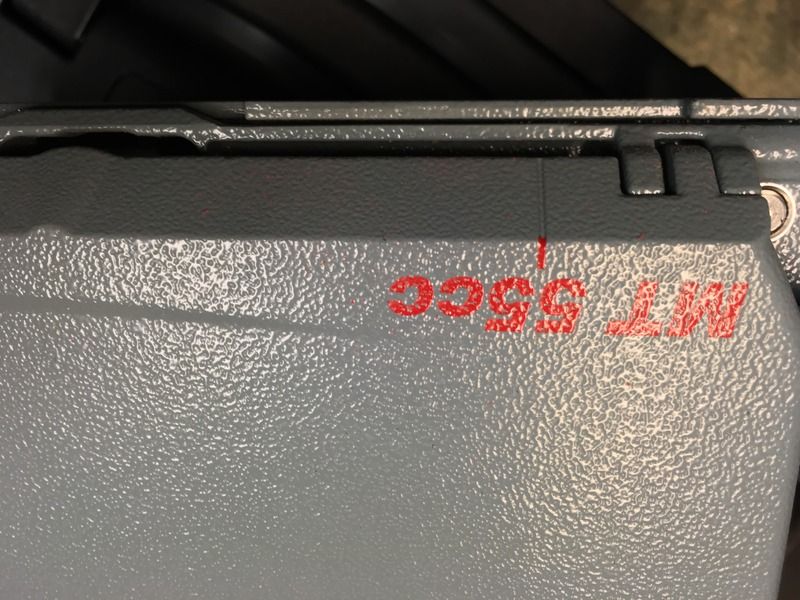

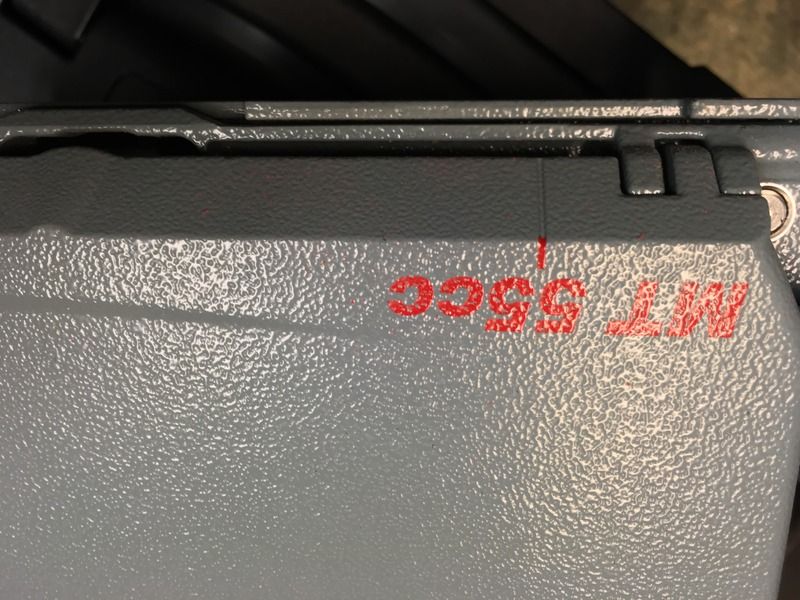

Post by henrun on Jan 5, 2017 12:55:49 GMT -5

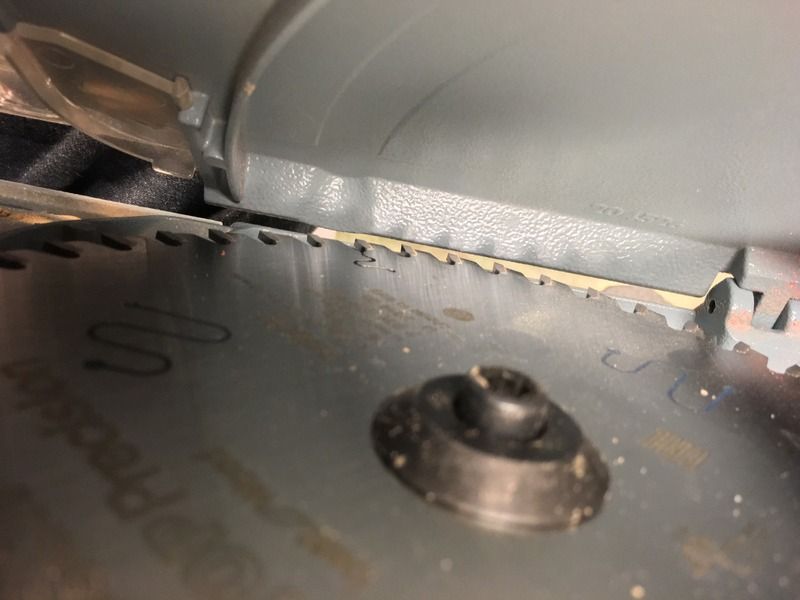

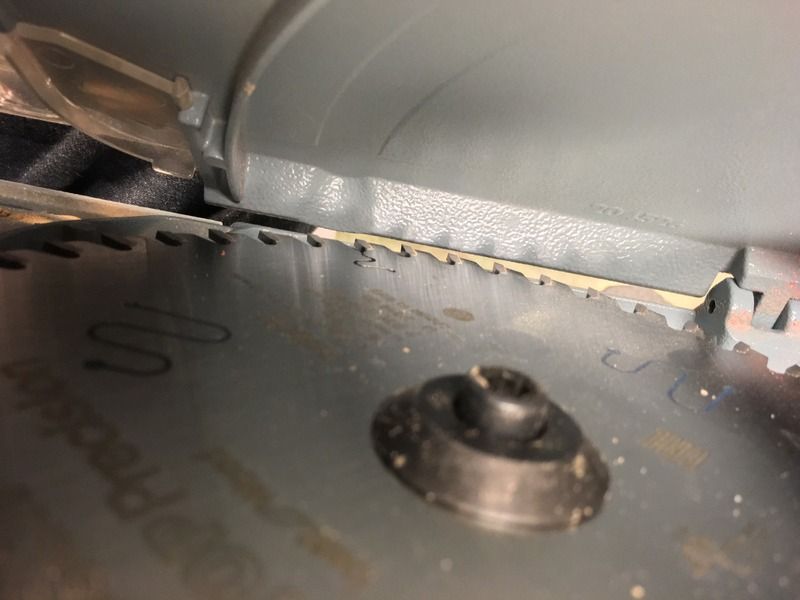

The blade does fit and does not protrude any when retracted inside the housing. When swinging the side open there is maybe half a mm clearance from the housing swivel but when closed there is enough room. I reckon it is impossible for the blade to wiggle or extend out from the spindle lock / center enough to scar the housing and when swinging the door open to release the blade the blade cannot spin so I think it will work just fine. When swung open, but not completely, at this angle it looks like the blade is touching, but it clears, barely:  Retracted and clearance from the housing:    Since I always have some sacrificial material or clearance I won't worry about the extra cutting depth. I think it is almost impossible to exert enough pressure to the housing to cause the housing to touch the blade in actual use. The blade spins freely (tried it before locking down the blade nut). |

|

|

|

Post by toomanytoys on Jan 5, 2017 14:12:53 GMT -5

Thank you for checking the fit and responding back.

|

|

|

|

Post by calidecks on Jan 5, 2017 15:24:36 GMT -5

The blade does fit and does not protrude any when retracted inside the housing. When swinging the side open there is maybe half a mm clearance from the housing swivel but when closed there is enough room. I reckon it is impossible for the blade to wiggle or extend out from the spindle lock / center enough to scar the housing and when swinging the door open to release the blade the blade cannot spin so I think it will work just fine. When swung open, but not completely, at this angle it looks like the blade is touching, but it clears, barely:  Retracted and clearance from the housing:    Since I always have some sacrificial material or clearance I won't worry about the extra cutting depth. I think it is almost impossible to exert enough pressure to the housing to cause the housing to touch the blade in actual use. The blade spins freely (tried it before locking down the blade nut). I'm curious to know if heat will cause it to expand enough to hit. |

|

|

|

Post by reflector on Jan 5, 2017 16:13:11 GMT -5

Yikes that's a tight fit. The thermal expansion is another factor, maybe an email to Bosch asking them how much the blade can expand from regular heating in use might be in order. Otherwise letting the blade fully stop outside of the housing would probably be the safest option... On another note that's another set of blades the MT55cc can use. Mafell blades (Leitz?), Festool blades (Actually Leitz), Tenryu, Oshlun, Triton (165mm), Infinity, Trend, Makita (I suspect, its a 165mm saw) and Freud (Bosch blades are Freud). Only two of those brands (Trend, Bosch's European line of blades) are "NAINA." Otherwise I guess any of the European 165mm blades (As in construction blades) would work in a jiffy, as well as the European equivalent 6-1/4"-ish diameter blades with a 20mm bore. Choice is good.

Curiously this would bring the MT55cc to 58.5mm in maximum cutting depth... 53.5mm with the track. I suspect if the green koolaid forum guys found that they had some space in their crosscutting saw it'd take some anguish away from them. Or cause more/less infighting depending on how the discussion goes. Something about a HKC55 and dimensional lumber. I'll just leave that there for anyone outside of the MUF that isn't a rabid fanboy that's willing to experiment with non green koolaid brand accessories.

|

|

|

|

Post by holmz on Jan 5, 2017 21:00:58 GMT -5

Thermal coefficient of expansion (TCE) is low for steel.

The actual temperature that the blade gets to is usually less than 200C (I would estimate)

The equation is:

(200c - ambient) * TCE * 165mm = diameter increase

(I doubt it is more than 0.1 mm )

|

|

|

|

Post by arvid on Jan 5, 2017 23:00:06 GMT -5

Thermal coefficient of expansion (TCE) is low for steel. The actual temperature that the blade gets to is usually less than 200C (I would estimate) The equation is: (200c - ambient) * TCE * 165mm = diameter increase (I doubt it is more than 0.1 mm ) I've cut radius cuts with a circular saw and got the blade hot enough to see it wobble a lot. Wether it expanded I cannot say but the blade would look like a dato blade spinning until it cooled down and straightedge out. Back when we made do with the tools we had |

|

|

|

Post by calidecks on Jan 6, 2017 0:18:19 GMT -5

Thermal coefficient of expansion (TCE) is low for steel. The actual temperature that the blade gets to is usually less than 200C (I would estimate) The equation is: (200c - ambient) * TCE * 165mm = diameter increase (I doubt it is more than 0.1 mm ) I've cut radius cuts with a circular saw and got the blade hot enough to see it wobble a lot. Wether it expanded I cannot say but the blade would look like a dato blade spinning until it cooled down and straightedge out. Back when we made do with the tools we had It's still quite common to cut framing radiuses with a skilsaw. Especially if it gets stucco. |

|

|

|

Post by henrun on Jan 6, 2017 0:52:07 GMT -5

It is still a full mm and a half to the housing at the tightest side of the blade / nearest housing part and downwards the slit is of course impossible to tear into.

The picture where the blade is almost touching the housing is a position in which the housing will never be in, with the housing closed, which it will always be under operation. So the risk of thermal expansion causing the blade to hit the housing is smaller than it looks. Blade wobble would apply to the standard blade too if that was the case - the blade is not thicker than Mafell blades.

Considering the blade is not a ripping blade I am not too concerned with heat, the blades I have for the Bosch are fine cutting blades.

Of course I will exercise caution and make a proper trial run but unless I am fitting ripping blades of the same size I think it will be fine.

|

|

|

|

Post by henrun on Jan 8, 2017 17:01:08 GMT -5

Ok, I have now tried the blade and it definitely works without problem. I did some cutting with the blade after a brief anxious dry run and I did cut 45mm studs down (although it is certainly not the best suited blade for it!) and no problems with hitting the housing. I am not endorsing the use of larger blades but in my case I now have two fine cutting blades that I can use on top of my blades for the MT55cc.

|

|