|

|

Post by MrToolJunkie on Aug 22, 2020 9:03:59 GMT -5

FWIW, the base twist issue on Bosch seems to be a non-issue as the knobs are tightened out of square at the factory. I think users release tension and tighten them correctly and it seems most are fine. I do not think there is anything wrong with Bosch and I would not hesitate to buy one..

The Mafell is not much more in my opinion and worth the convenience factors and quality in my opinion. A few dollars/ pounds is long forgotten if cost is a main concern. Even 240 pounds, spread over the life of the tool, becomes less of a factor. The is just me.

|

|

|

|

Post by alvychippy on Aug 22, 2020 12:25:09 GMT -5

FWIW, the base twist issue on Bosch seems to be a non-issue as the knobs are tightened out of square at the factory. I think users release tension and tighten them correctly and it seems most are fine. I do not think there is anything wrong with Bosch and I would not hesitate to buy one.. The Mafell is not much more in my opinion and worth the convenience factors and quality in my opinion. A few dollars/ pounds is long forgotten if cost is a main concern. Even 240 pounds, spread over the life of the tool, becomes less of a factor. The is just me. Nope! Believe you me, I was heart broken, when on a second day of intended use I discovered mine to be twisted. I considered to try bending it back, but reason why it was bent was very clear - too weak and during transportation in the box, due to not both sides equally locked, with reasonable minor knock gets twisted. Once I got Mafell, I checked the bases, and even they at first glance appeared identical, they felt different to touch. While load of videos eventually had confirmed so |

|

iban

Full Member

Posts: 111

|

Post by iban on Aug 22, 2020 13:37:36 GMT -5

FWIW, the base twist issue on Bosch seems to be a non-issue as the knobs are tightened out of square at the factory. I think users release tension and tighten them correctly and it seems most are fine. I do not think there is anything wrong with Bosch and I would not hesitate to buy one.. The Mafell is not much more in my opinion and worth the convenience factors and quality in my opinion. A few dollars/ pounds is long forgotten if cost is a main concern. Even 240 pounds, spread over the life of the tool, becomes less of a factor. The is just me. Nope! Believe you me, I was heart broken, when on a second day of intended use I discovered mine to be twisted. I considered to try bending it back, but reason why it was bent was very clear - too weak and during transportation in the box, due to not both sides equally locked, with reasonable minor knock gets twisted. Once I got Mafell, I checked the bases, and even they at first glance appeared identical, they felt different to touch. While load of videos eventually had confirmed so Did you try to fix the twisted base as they explain in the video? |

|

|

|

Post by mafellme on Aug 22, 2020 18:00:35 GMT -5

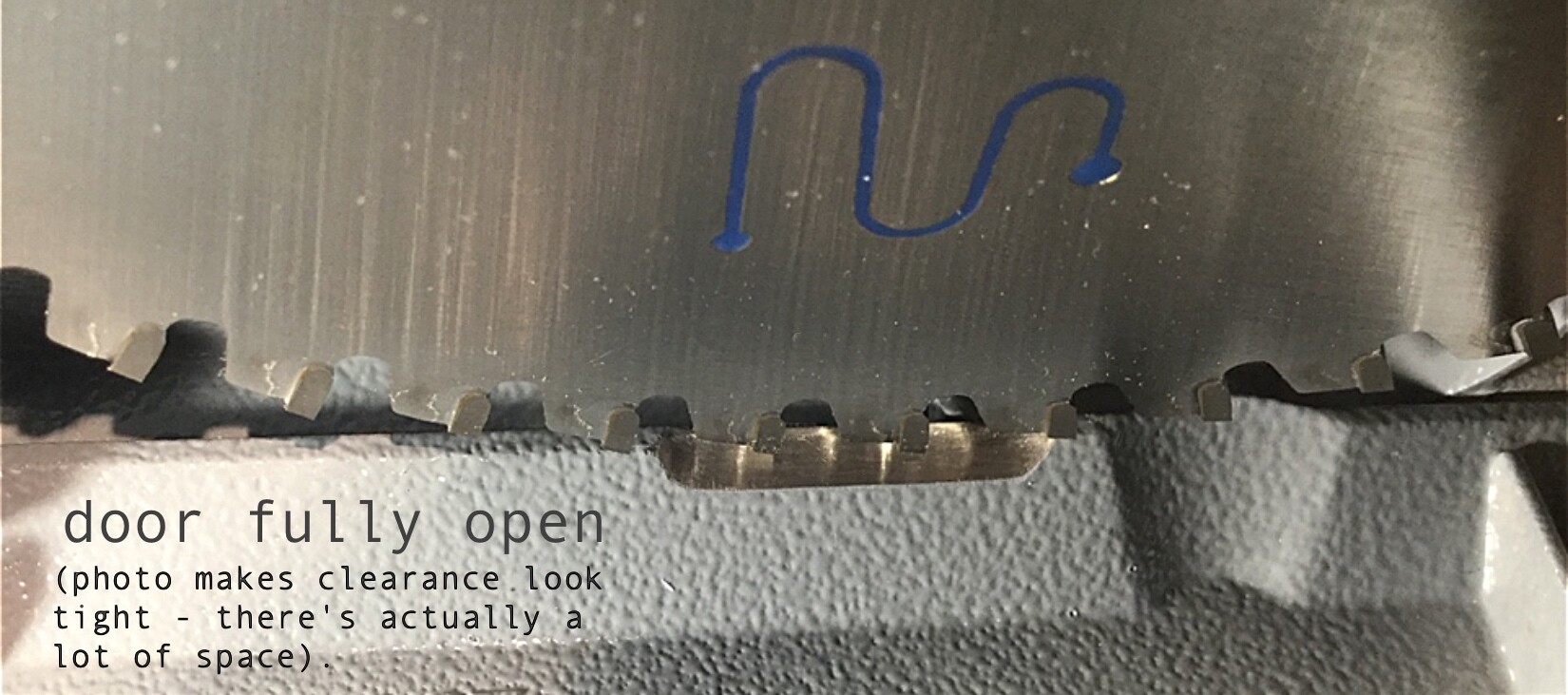

Do you need to do any modification in tha saw? Depending on how door pins were drilled at factory (+/-) the teeth on a 165 might slightly brush the bottom of door when fully opened for a blade change. Haven’t heard others complain of this so I assume mine was on the minus side. I notched the inside of my door (can’t tell from outside / door closed) for clearance but didn’t really have to. When door is closed, unmodified, there are no clearance issues at bottom of door. During a plunge there are no clearance issues either. Only when blade is returned does it have a chance of slightly / momentarily scoring top of inner shroud - due to force of rebound hitting a concealed urethane bumper and closing the distance on what was tight clearance at the top. (instant machining). It’s rare that I need the extra 1.5mm depth of running a 165, more to do with blade options. It’s just a tool, though a good tool, so I don’t mind modifying it somewhat. If you get your mafell you could spin a 165 with door opened / saw de-energized (defeat door lock by pushing in with screwdriver) and decide on clearances yourself.  (edit: photo got corrupted on host - had to upload new image) It's not necessary to remove any metal from the bottom of the door, with a file, in order to fit a 165mm blade. I took photos for the following description, but then found out the forum has no more storage allowance. However, I'm not going to waste time using an image hosting service as they'll delete the pics in a month or so, anyway. I simply removed the depth stop component from the saw (the black plastic arc with the sliding depth adjuster). This is easily removed by removing a torx screw near the top of the component, and another screw which can be accessed at the bottom of the component, from the INSIDE of the blade enclosure (i.e. you need to open the blade door to find the screw head). If you do this, you will be on your way to invalidating your warranty, so I am not encouraging anyone to do this - I'm simply describing what I did, personally, so that I could use 165mm blades in my own saw. Also note that the two removed screws are different from each other - the skinnier one goes at the bottom, inside the blade enclosure. Once that black plastic depth adjuster has been lifted off the saw, you can then see a tan-coloured (urethane?) cylinder, that acts as a bump-stop which limits how high the saw blade can return into the housing, on its way upwards after a plunge cut has been completed. It is possible to very carefully (and incrementally, so you can test as you go) shave a flat into the side of this urethane cylinder, to permit the plunge carriage to return a millimetre or two higher than it normally would do. This allows the blade to rise a millimetre or two higher within the blade enclosure, thus allowing the enclosure door to hinge fully open without snagging on the teeth at the bottom of a 165mm blade. I had to be really careful with how much I shaved off the bump stop, so that it was just sufficient to allow the door to hinge fully open without snagging on blade teeth, but also not so much that the 165mm blade would then start eating into the casting at the top of the blade. There is very, very little margin for error, so it took me a while, to shave and test, shave and test, incrementally. |

|

|

|

Post by kraftt on Aug 22, 2020 20:16:13 GMT -5

Interesting approach. Though the one and only place where clearance could be an in-operation issue is at the top of the blade housing. So lessening that distance by shaving the bumper seems counterproductive. With 165’s in use the upper housing stands to get scored from any hard rebound so I chose not to add to this.

As mentioned, I didn’t need to notch my door and doubted that others would require the clearance.

Upon first try closing & opening door with a 165, mine scuffed the door paint. Thought it would be nice to have a comfortable distance because the door does ‘bounce’ when you drop it. Turned out to be one of those things where I'm glad I did it afterwards.

So I went the opposite approach, knowing bumper will only compress more over time/use, and added a tiny stick-on pad to the metal stop that hits the bumper. The idea being it gave more blade space at the top and my door notch allowed for the new lower / added bottom depth.

Of course the stick-on pad / spacer eventually fell off (there are permanent solutions but I’m not bothering) and I noticed a superficial score on the upper housing thus solving the max rebound issue as far as I was concerned. But blade changes are nice.

|

|

|

|

Post by mafellme on Aug 23, 2020 5:36:18 GMT -5

To be completely honest, when I first bought my '55, I treated it with kid gloves, and I still treat it with respect and choose not to abuse it (it is very rare for me to abuse ANY of my tools). However, I became so cheesed-off with the nonsense of being expected to pay way over the odds for Mafell's 162mm blades that I decided there was no point in avoiding using widely-available (and more fairly priced) 165mm blades if it meant that my 'perfect condition' '55 was used less (to preserve the expensive 162mm blades) or used as much as I like but with over-used and therefore less-than-sharp 162mm blades. It simply became obvious that the most rational way to get the most out of my investment in a '55 was to stop being overly concerned and just go ahead and (carefully!) tweak the saw so I could use 165mm blades to my heart's content. I'm so glad I saw the sense of this approach and I haven't looked back, ever since. I can happily buy 40-tooth Freud 165mm blades for LESS than HALF (yes, really, I am not exaggerating) the price of Mafell 48-tooth blades. I know about Key Fixings 162mm blades, but I've seen conflicting comments about the quality of the carbide, so I choose not to go down that rabbithole, especially as the Freud 165mm blades are still significantly cheaper. I should also point out that I don't consider Mafell's decision to implement 162mm blades to have been a legitimate one. They know damn well that the market is well-stocked with 165mm blades (and moderately well with green-friendly 160mm blades). I suspect Mafell just felt like keeping blade choices semi-proprietary, by going with 162mm for the '55. Certainly, the '55 has more than enough torque to drive a 165mm blade (a point unequivocally proven by the less-premium Bosch GKT 55 GCE running 165mm blades, as standard) so dropping the diameter by 3mm does not seem to me to be at all justified. As much as I appreciate the quality, design, and engineering of Mafell's tools, I feel they are disrespectful to their customers, in the way they charge extortionate prices for accessories. Sure, the green company behaves even worse, in this regard, but Mafell definitely do it to a significant degree and I refuse to play that game, whenever I can work-around it. In a nut-shell, then, I concluded that if 10 Mafell blades cost as much as an entire brand new '55, then why should I be concerned about any tiny shaving of the blade path within the enclosure casting, if I can cut my blade costs by approximately 2.5 times? Over the past year, the bump stop has continued to perform very well in its modified state, although I will admit that a sudden retraction or two of the plunge mechanism has now led to a small section of paint being removed from the top of the inside of the blade enclosure, where the top of the blade has evidently skimmed the casting, but I assure you it is _VERY_ minimal. It's not that I cut the urethane too far, it's just that the urethane has some 'give' to it, so on rare occasions when the plunge rises with more momentum than usual, a bit more force and therefore compression occurs, and therefore a tiny skimming of the paint. If 10 Mafell 162mm blades cost the same as a whole new saw, then have I really lost out by losing a tiny fraction of paint on the inside of the saw? I say no ;-)

I'm happy with the method of modification I chose and I would do it again, 500 times, in a heartbeat.

|

|

|

|

Post by alvychippy on Aug 23, 2020 12:24:44 GMT -5

Nope! Once both sides released, saw was freestanding and rocking on front left and rear right point of the base by 2mm. Thus is how I've learned it being twisted - at the time of pushing the saw down it clicked.... The only way to rectify is to physically bend the base back, but once (twice) bent it'll be weak as anything, hence returned promptly Couple of weeks later, I've come across this video |

|

iban

Full Member

Posts: 111

|

Post by iban on Aug 23, 2020 12:49:20 GMT -5

I´ve just noticed Mafell blades are 162 or 160mm, 1,8mm teeth width, 1,2mm blade width and what I have for my Bosch is:

Expert for wood.

165mm, 1,5mm teeth width, 1mm blade width (which supposedly are blades optimized for battery)

and

165mm, 2,6mm teeth width, 1,6mm blade width.

Will the teeth width have any impact in the saw performance or it is between its tolerances? I mean apart from the guide rubber which will be affected compared with the rubber cut by the mafell blade.

Why did you choose to use 165mm over 160mm? Because 160mm is also pretty standard from what I can see. Is because the extra 5mm cut depth?

160mm are a little bit more expensive but only a couple of euros from what I can see.

Bosch Expert for wood which should be good blades 160mm 1,8mm teeth are about 28€. I think it is a good relation price/quality

|

|

iban

Full Member

Posts: 111

|

Post by iban on Aug 23, 2020 12:52:52 GMT -5

Nope! Once both sides released, saw was freestanding and rocking on front left and rear right point of the base by 2mm. Thus is how I've learned it being twisted - at the time of pushing the saw down it clicked.... The only way to rectify is to physically bend the base back, but once (twice) bent it'll be weak as anything, hence returned promptly Couple of weeks later, I've come across this video  I think I'm beginning to want to stay away from the Bosch |

|

|

|

Post by kraftt on Aug 23, 2020 13:18:02 GMT -5

I´ve just noticed Mafell blades are 162 or 160mm, 1,8mm teeth width, 1,2mm blade width and what I have for my Bosch is: Expert for wood. 165mm, 1,5mm teeth width, 1mm blade width (which supposedly are blades optimized for battery) and 165mm, 2,6mm teeth width, 1,6mm blade width. Will the teeth width have any impact in the saw performance or it is between its tolerances? I mean apart from the guide rubber which will be affected compared with the rubber cut by the mafell blade. Why did you choose to use 165mm over 160mm? Because 160mm is also pretty standard from what I can see. Is because the extra 5mm cut depth? 160mm are a little bit more expensive but only a couple of euros from what I can see. Bosch Expert for wood which should be good blades 160mm 1,8mm teeth are about 28€. I think it is a good relation price/quality I use a variety of blades in different plate / kerf. All work fine. Tooth count seems to make the most difference to me perception of power, but I'm corded (for now). I think someone could go 160 (mo power) for the life of the saw and be perfectly happy. The 162 only adds 1mm depth of cut and the 165 adds another 1.5mm (or 2.5mm over a 160). But because I get creative with this versatile saw I like having the option of 165 on hand if the rare circumstances arise so as to not slow workflow - that's about it. Here's an old gif I made pointing out that just because the tooth / kerf is wider than another blade the plate thickness factors in too.  |

|

|

|

Post by mafellme on Aug 23, 2020 13:24:57 GMT -5

I´ve just noticed Mafell blades are 162 or 160mm, 1,8mm teeth width, 1,2mm blade width 1.8mm - 1.2mm = 0.6mm

half of that offset exists on each side of the blade, so 0.6mm / 2 = 0.3mm

That means that the actual cutline of that blade will be offset to the left of the machine spindle by 0.3mm.

1.5mm - 1.0mm = 0.5mm

0.5mm / 2 = 0.25mm cutline offset

2.6mm - 1.6mm = 1.0mm

1.0mm / 2 = 0.5mm cutline offset

So, yes, as you've already gathered, the guide rubber will be affected by using a variety of blades (although, personally, I don't use such a wide range of blade thicknesses/offsets as you have. Mine are very similar to each other).

As for machine performance, I've never tried mine with a 2.6mm kerf

blade, so I'm not in a position to reliably pass comment on that.

However, I have often noticed people claiming that the TS55 is

underpowered, and wondered whether that reputation might partially be blamable on Festool using quite thick kerfed blades.

It seems blade popularity and availability vary somewhat by geographical location. In the UK, 165mm is the most widely available, and, as I mentioned, I can get high quality (not absolute premium quality, but very decent quality Titanium-Cobalt carbide teeth) 165mm Freud blades economically. A 24-tooth 165mm Freud blade costs me approximately £16. A 40-tooth 165mm Freud blade costs me approximately £19. For me, that makes choosing to use these 165mm blades in my MT55cc an absolute no-brainer.

I do sometimes buy Bosch Expert For Wood blades (the silver 165mm ones - 2608642384, 1.8mm kerf, 1.3mm plate thickness), but not often, as the Freud blades do what I need, just as well, for less money.

|

|

|

|

Post by alvychippy on Aug 23, 2020 16:29:19 GMT -5

Just FYI Freud are great blades, most are 1.7 kerf, BUT teeth configuration isn't suitable for none Formica or Trespa/Minerva cutting, due to too steep angle of the teeth on them.

|

|

|

|

Post by mafellme on Aug 23, 2020 17:03:33 GMT -5

Just FYI Freud are great blades, most are 1.7 kerf, BUT teeth configuration isn't suitable for none Formica or Trespa/Minerva cutting, due to too steep angle of the teeth on them. There is truth in what you say, but it's 'horses for courses' - personally, I only ever have to cut laminated chipboard (generic Formica), melamine, or solid timber worktops, which I find the Freud ATB blades cope with just fine. I'll admit that one thing I don't like about the Freud 165mm ATB blades I frequently use (LCL6M01062 & LCL6M01064) is their hook angle of 15 degrees, but I can't really expect miracles for less than £20 a blade! www.ffx.co.uk/tools/product/Freud-Lcl6M01062-8025331498274-165-X-1.7-X-20-X-24T-Trim-Saw-Bladewww.ffx.co.uk/tools/product/Freud-Lcl6M01064-8025331498328-165-X-1.7-X-20-X-40T-Trim-Saw-Blade(please ignore the incorrect tooth diagrams in the above product listings) Although I've never needed to use it, in the unlikely event that I'm ever asked to work with Trespa or similar, I have a Freud LP91M (zero-degree rake, TCG) blade on-hand, sitting at the bottom of my MT55 systainer: www.ffx.co.uk/tools/product/Freud-Lp91M-001-8025331516893-160-X-2.0-X-20-X-30T-Ultimate-BladeIt's the only 160mm blade I have, it's the thickest blade I've ever bought for the MT55 (2.0mm), and it's never been out of its packet, since I bought it. I notice the price has gone up in the past month (it was about £27 at the above link). It's funny you mention Trespa - I read, last night, on one of the many threads here on MUF, that someone was suggesting that aluminium-cutting blades cut Trespa just as well as dedicated Trespa blades. Given that they have zero or slightly negative rake, I suppose that's quite possible, but I've never needed to cut Trespa, myself, so I've never tried using an aluminium-specific blade for the purpose. Do you cut much Trespa? |

|

|

|

Post by alvychippy on Aug 23, 2020 19:21:02 GMT -5

Quite a bit of "Minerva" the older/cheaper range and recently had 2 big'ish jobs with Trespa. They are almost identical, behave almost the same, but both require specific ways of working with them (learned loads in the last couple of jobs, as it was mainly worktops) Slow speeds Big torque saw Ridgid (thick) blades (either triple cut or "flat" aluminium) Router cutters got to be sharp as anything and really "torqued" router has to be significant wattage 1700w+ God forbid, you end up indecisive and slow down, heating/melting works inwards, shows up immediately. ANW, as it came to blades ATF turned out horrible, fine Formica 80t started deflecting, triple chip already has been a touch blunt (TBH and trial and error aluminium - test blade from Screwfix 160mm 2mm kerf ~£13) had produced superb results. And yes Freud LP91M 001 seems to be spot on for the job. www.amazon.co.uk/gp/aw/d/B0065DWADQ/ref=psdcmw_1939162031_t2_B008HRGR28The "go to" blades I have for everything |

|

iban

Full Member

Posts: 111

|

Post by iban on Aug 24, 2020 15:57:37 GMT -5

Have you compare those Top Precision Best for wood, the silver ones, to the Expert for wood (blue)?

Apparently same teeth angle and number, and blue ones are in the same blade and teeth width.

It is supposed (if I´m not wrong) that Expert is better than Best for Bosch

|

|